Forging is a well-established manufacturing process being used over centuries. Over the years, rather decades, the industry has evolved and Industrial Forgings has taken a center stage in manufacturing components which are critical to a Process. With the increase in importance and need for standardization across Industries and Geographies, various standards like ASTM, ASME ANSI and the likes have been formulated.

Challenges In Industrial Forging Manufacturing:

The challenges start with procurement of the Raw Material and its stocking. Every stage of manufacturing has to undergo tests to ensure adherence to the Quality Standards thus making the compliance complex and prone to mistakes / re-works. Following are some of the challenges faced by the industry:

Procurement

- Ordering of Material in different sections and sizes as per the ASTM grades

- Stock visibility in different shapes, grades and sizes

FG Item Configuration

- FG item has many attributes and mapping of all attributes with the Item code.

Production Planning

- Clubbing of same forging size of same grade material

Quality Compliance

- Tracking RM to Forged Components

- Tracking Quality Parameters (QP) of incoming material with respect to vendor/supplier values.

- Compliance to ASTM standards for the Forged Items.

- Tracking the tests to be done as per the customer needs and the material grade

- Compliance to customer specific ASTM parameters – a deviation from the standard parameters for customer specific forgings.

- Listing of tests to be performed on the Item.

- TPI call outs and follow-ups

- QAP and Certificates generation and record keeping.

Production & Dashboards

- Tracking Customer Order line item numbers with Production and sales data.

- Customer Work Order Life Cycle

- Customer Follow-ups for Payments – milestones as per progress of the WO.

- Purchase Order Life Cycle

- Timely visibility of Work Orders at pre-defined status of the Work Order

- Customer receivables Tracking

Addressing Challenges through DigiSec ERP:

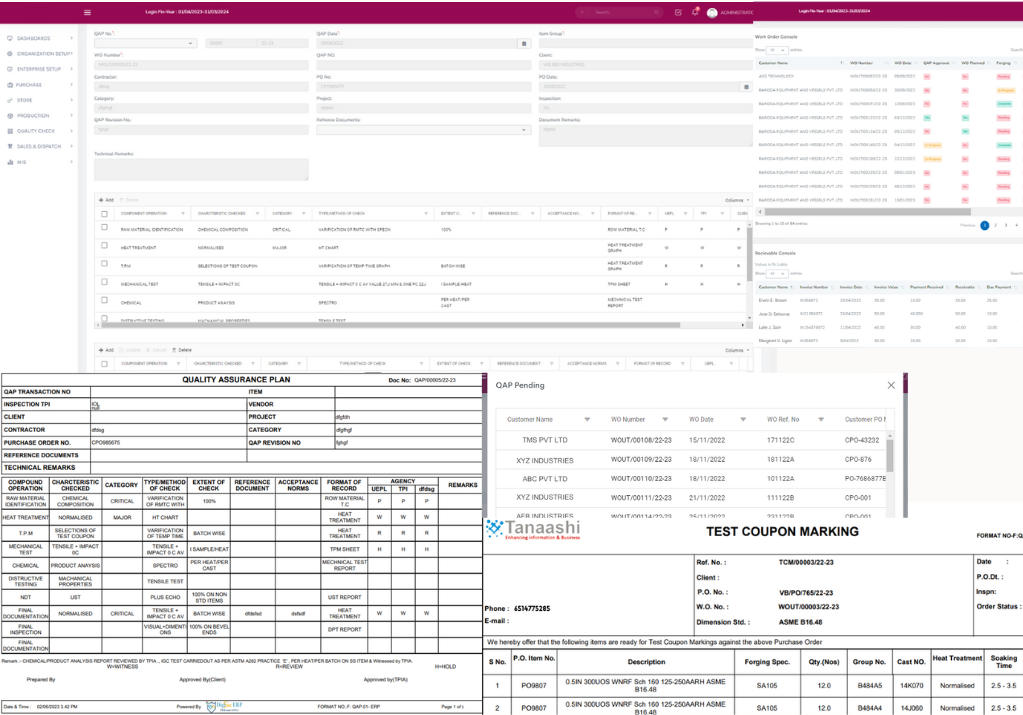

The above challenges have been addressed in this ERP through in-built libraries and various automated configurators and dashboards. The hosted model makes it all the more easier for the users to access it from anywhere. The following features help in addressing the above issues and many more:

- The ability to provide quantity variance at the PO item level and maintaining various sizes through the lot number definition ensures easy stock visibility.

- The quality libraries at the Material Grade level like ASTM A105 are well defined for mechanical, Chemical and other tests. The user can further define client specific standards under these main standards and tag them to the Item. This ensures “zero mistake” while performing client-specific test and seeking approvals.

- The item is defined through a configurator with all possible attributes/parameters and hence it becomes easy to export and plan production for a particular size and kind of Forgings.

- Role-based dashboard access ensure desired information to the desired people. Complete customer order life cycle and some other dashboard widgets like Payment Due, WO alerts based on various stages like Under Process, held due to constraints etc enables timely information to the users for quick actions.

The web-based SaaS architecture and being mobile compliant make it all the more accessible and user-friendly for the users. Integrations with communicators like Email, and Whatsapp helps the users in timely updates.

In the forging sector, using such an ERP system can result in greater productivity, better resource utilization, increased customer satisfaction, and raised competitiveness. It offers a centralized platform for controlling various company activities, allowing forging businesses to adjust to changing conditions in the marketplace, cut expenses, and promote growth.