Commonly asked and deliberated questions are

What does MES signify?

Why is it important? Does it bring in credibility or is just another technology gig?

TRUTH, TRUST & TRANSPARENCY – These 3 T’s are the foundation of why MES should be adapted. It is also a step for any manufacturing organization which truly wants to implement Industry 4.0.

Today’s fast-paced manufacturing process needs complete and accurate real-time data from the shop floor. An MES system ensures excellent monitoring and synchronization throughout the factory, resulting in high productivity and market response.

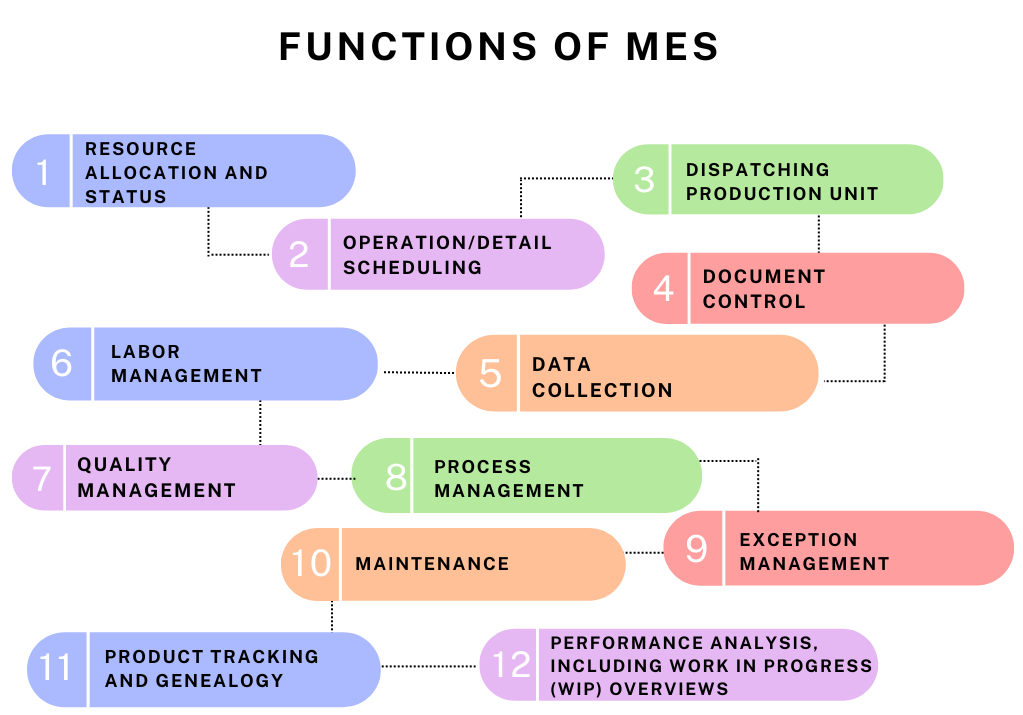

MES is a system that eases the process of the manufacturing organization it manages the complex process to automate the real-time data.

MES/IIoT is a system interconnected with physical devices that work with the internet and flow the data to the system, applications that reduce the manual work and add accuracy at work.

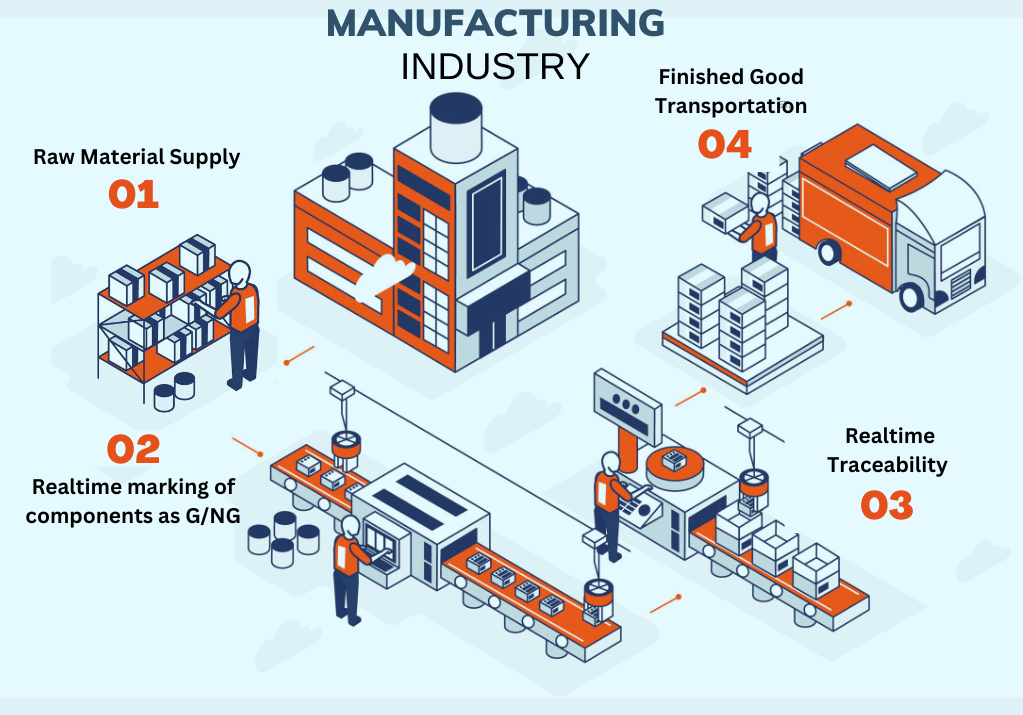

Manufacturing operation seems complex but an integrated manufacturing solution helps you to gain control of production and maximize productivity. Production success necessitates the ability to regulate and track manufacturing processes.

A manufacturing execution system (MES) is a powerful tool that digitizes and automates batch production, filling, and packing tasks. The system’s built-in validation capabilities ensure that every stage of production works smoothly and that all procedures are performed correctly. This not only minimizes errors but also reduces waste and lowers costs, providing the foundation for lean performance improvements.

Benefits of having a Manufacturing Execution System

MES is a technology that enables data to flow from a network (local or distributed) to all other networks. An MES automation system can enhance bottom-line profitability, on-time delivery, and product quality significantly. There are other features too of MES:

- Real-time consumption as per Bill of Material

- Real-time Traceability

- Reliable and precise planning

- Real-Time Tracking of G/NG

- Solution Flexibility

- Global-View of Information

- Eliminate paperwork

What benefits Integration of MES with ERP?

ERP systems are a type of software that centralizes billing, accounting, logistics, inventory, human resources, and customer relations information on a single platform.

MES enables the organization to monitor real-time data of manufacturing operations, from raw materials through the planning and execution of production orders from the ERP to the dispatch of finished goods.

If the organization wants to increase transparency, communication, and collaboration the whole organization can achieve it by integrating ERP and MES systems. This is the way companies create a data ecosystem to optimize forecasting and inventory management, avoid production delays, increase productivity, and reduce business risks by detecting problems on the shop floor faster.

Both MES and ERP have the ability to work together if you are thinking of a Manufacturing Execution System or ERP System for your organization.

Feel free to contact us to know more about MES / IIoT and how it can be implemented.